on all UK & Ireland orders

on all UK & Ireland orders

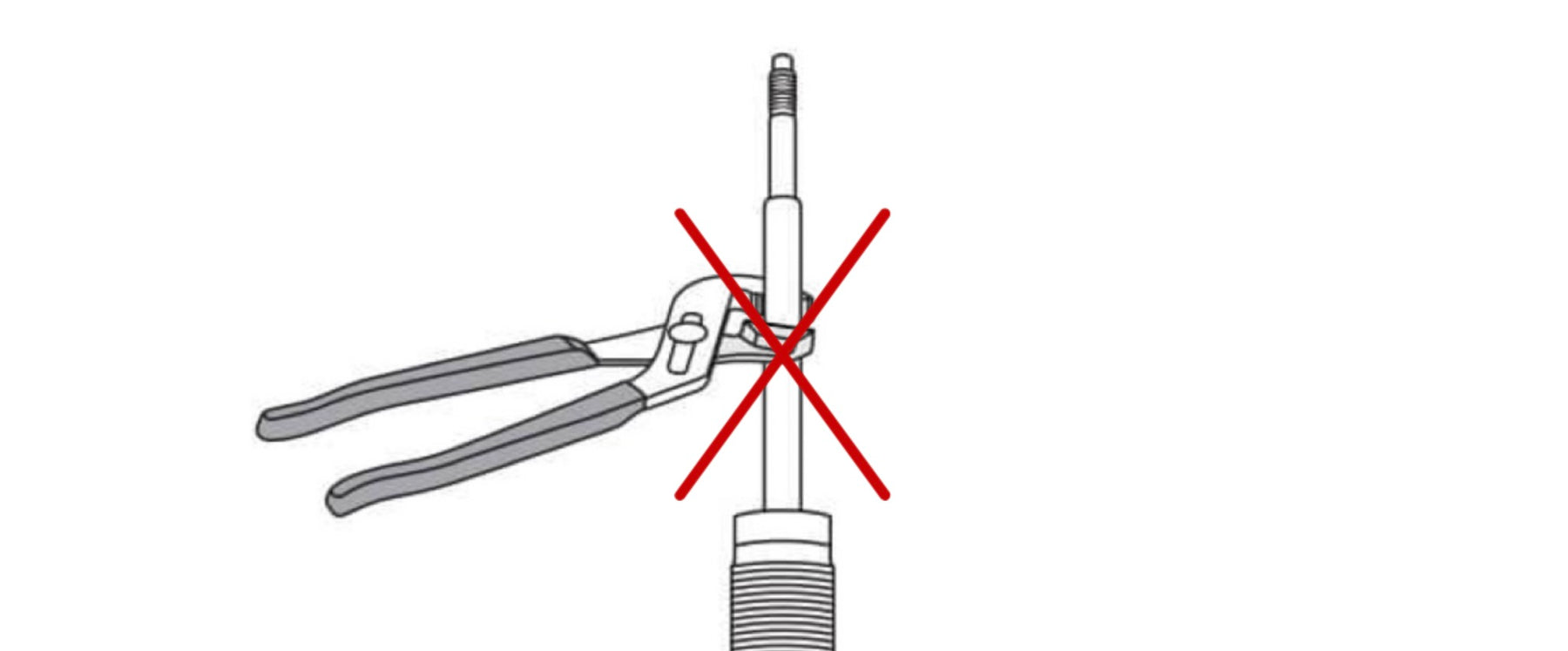

In every coilover kit we include a warning sheet, on this sheet you are told not to use tools on the piston rod also known as tooling the shock. We are seeing more of this happening than we would like to admit.

DONT's

Never hold the piston rod with pliers or vice grips. This will damage the fine surface of the chrome piston rod, causing the oil shaft seals to fail and leak. Without oil the shock absorber cannot function.

WHY

When the piston rod is held with pliers or grips this leaves gouges or teeth marks on the piston rod. Marks or gouges will then pass through the shock's oil seal as the vehicle is driven. Depending on how severe these gouges or marks are will result in an oil seal failure. This will result in oil leaking onto the shock body and rendering the shock useless.

Every time we have a customer email or call to complain of oil all over the shock two weeks after installation it is always due to using pliers or vice grips on piston rod.

DO's

There are two methods that can be used to properly tighten the top nut of the coilover kit. You can see those two methods detailed below.

BE ADVISED

Unfortunately damage to the shock absorber seals due to tool marks on the shock piston would not be classify as a manufacturer defect and therefore will not be covered under warranty. If a shock is replaced under warranty and the defective one that is sent back has evidence of this tool damage we will have to charge for the replacement.

Leave a comment